Microhole Drilling Expert Adds New Capabilities

Due to growing demand, Micromachining leader, Potomac Photonics, has significantly expanded its small hole drilling capabilities and operations by adding several new laser systems, spanning the UV through IR wavelengths, that are ideal for machining holes for applications such as catheter hole drilling, precision alignment of optical fibers, probe card devices and leak test holes. To offset any physical and/or cost limitations of laser processing, Potomac has also added a new Micro-CNC system that can mechanically drill holes as small as 100microns. By offering both of these machining technologies, Potomac provides a more complete solution for micromanufacturing.

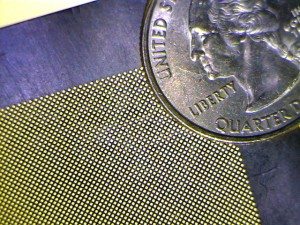

In addition to adding hardware, Potomac has developed new processes that allow for very precisely creating holes in a wide range of materials and thicknesses. For example, Potomac successfully completed a project in which 1,000’s of holes, as small as 4 microns, were drilled through 150-micron thick stainless steel. In another breakthrough, microholes, as small as 25 microns, were drilled through 1mm thick Tantalum. Utilizing state of the art Aerotech motion control systems that have been calibrated to NIST traceable standards, feature to feature positional accuracies can be held to submicron levels.

This expansion has also resulted in much shorter lead-times, with some projects being completed in less than 24 hours and most within 48-72 hours. “Potomac now drills millions of holes per day for a broad range of industries including medical, biotech, semiconductor, optical, and automotive,” stated Director of Operations, Mike Davis. “The ability to drill highly precise microholes is critical for the development of many new products and devices and we are committed to being on the forefront of this technology,” added Greg Behrmann, Potomac’s Chief Technology Officer.

ABOUT POTOMAC PHOTONICS

Potomac Photonics has been a leader in microfabrication for almost 3 decades. Potomac’s contact services span prototyping to production, helping clients develop miniature products and bring them to market. Utilizing cutting-edge manufacturing technology, Potomac has been recognized by both commercial and government agencies for innovation in areas such as medical device manufacturing and electronics fabrication. Potomac’s high-tech facility, located in Lanham, MD, is ISO 9001:2008 and ISO 13485:2003 certified.

Visit the website at www.potomac-laser.com