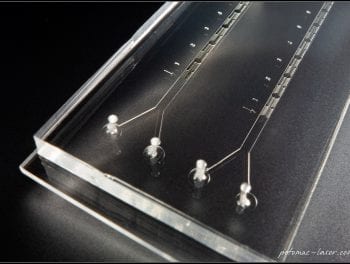

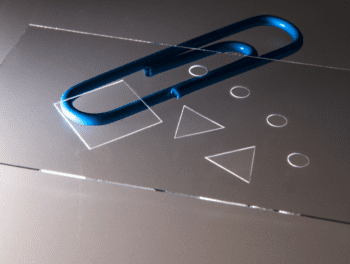

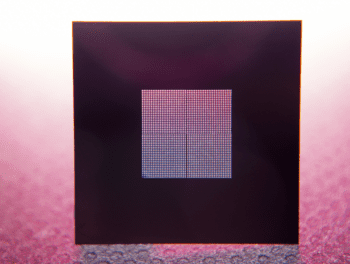

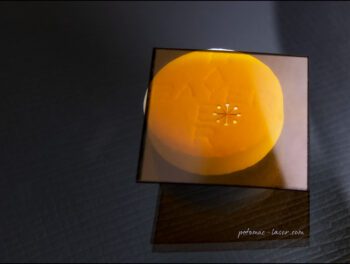

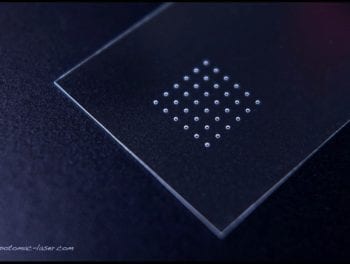

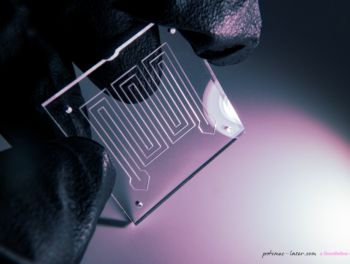

Goodfellow’s Acquisition of Potomac Photonics: The Ultimate One-Stop Shop for Micro-Machining and Materials

In a significant move that promises to revolutionize the field of micro-manufacturing and materials supply, Goodfellow has recently acquired Potomac Photonics. This acquisition is not just a merger of two companies; it’s a strategic integration that exemplifies the adage, “1+1=3.” Here’s why this combination is a game-changer for customers across various industries. Expanding Horizons: From…