Plastic Micromachining

Potomac Photonics has a broad range of technologies and processes to micromachine almost any type of polymer material on the market with features both small (down to a micron) and large. With the added benefit of being able to handle projects ranging from single prototypes up to full production runs of millions of parts, Potomac is truly your one-stop manufacturing solution. Examples of projects or applications that we have helped our customers develop and bring to market include:

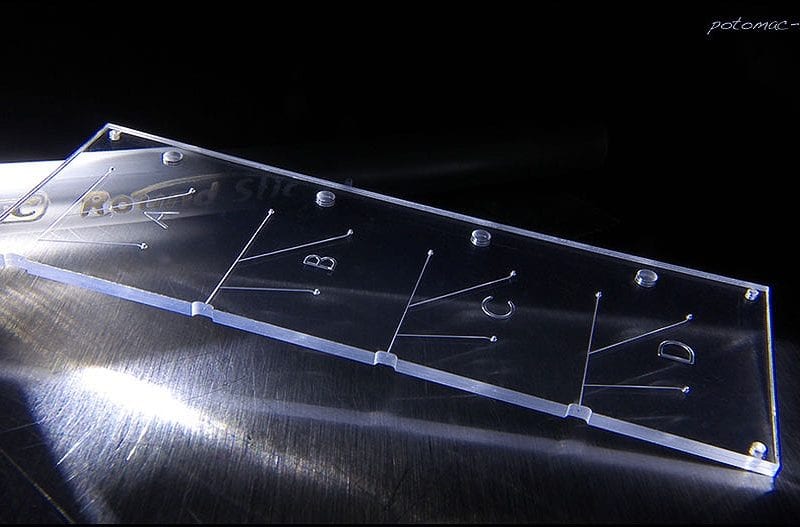

- Fabricating custom plastic parts

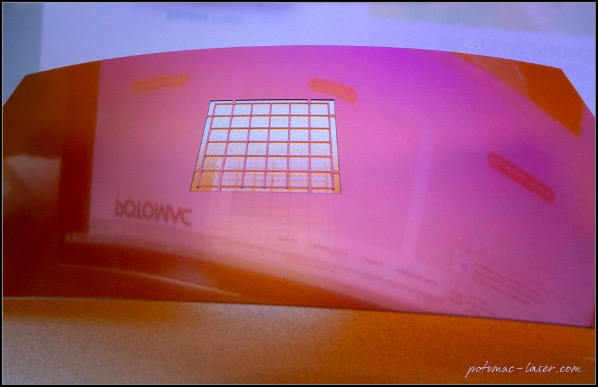

- Patterning of metalized plastics

- Precision cutting of polymers / plastics sheet

- Part singulation

- Polymer circuit excision

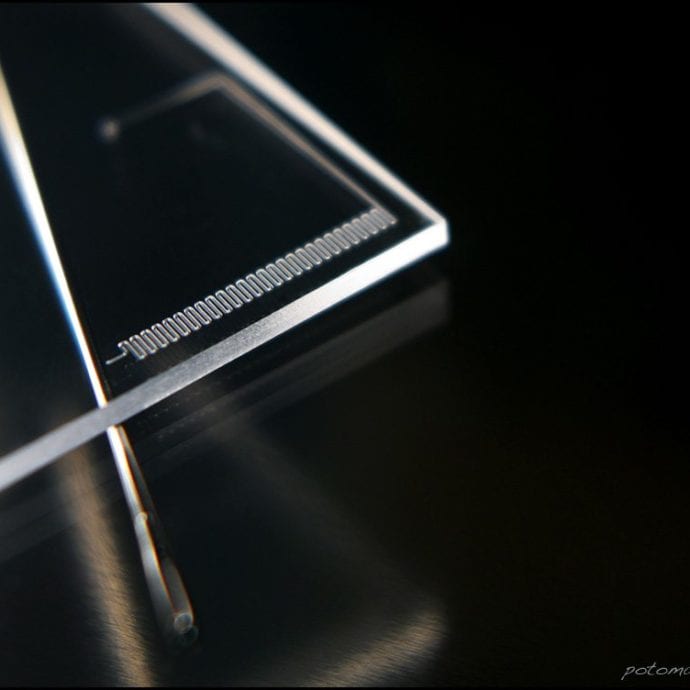

- Small hole drilling in almost any type polymer material

- Blind channels and holes

Potomac Photonics stocks many of the these polymer materials. If we do not carry the material, we have the ability to acquire it quickly from our list of qualified suppliers. Our goal is to be your one stop shop for custom plastic parts and materials. In addition, we do not have any minimum quantity policy, so you do not have purchase more parts or materials than you require.