Manufacturing the Future Seminars with 3D Printing 2.0 at Potomac Photonics

The seminars will be held May 8 from 10:00 a.m. to 12 Noon and June 20 from 2:00 to 4:00 p.m. A special seminar with an emphasis on the needs of educators will take place on Saturday May 10 from 1:00 to 3:00 p.m. and feature the popular Cube desktop 3D Printer.

In all seminars you will:

- Learn how 3D Printing 2.0 makes printers user-friendly, cost effective, rugged and reliable in the most demanding settings

- See how to choose the right 3D printer for any application, from a wide range of technologies and price points

- Get the latest updates on 3D Systems printers for full-color plastic printing, simultaneous multi-material composite printing, and high volume manufacturing

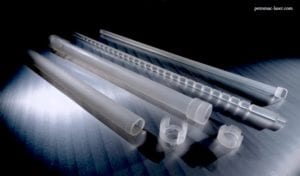

- Feel 3D Printed parts that deliver injection molding-like quality and learn about expanded materials options in metals and ceramics

Although there is no fee to attend, space is limited, so please register today. You’ll be on your way to understanding the power of 3D Printing 2.0.

- Register for the May 8, 2014 seminar here.

- Register for the June 20, 2014 seminar here.

- Register for the Educators seminar on May 10, 2014, here.

For over 30 years, Potomac Photonics has been a leader in microfabrication and small hole drilling. Potomac’s contract services span prototyping to production, helping clients develop miniature products and bring them to market. Using cutting-edge manufacturing technology, Potomac has been recognized by both commercial and government agencies for innovation in areas such as medical device, electronics, aerospace, and automotive manufacturing. Potomac’s high-tech facility, located at bwtech@UMBC Research and Technology Park , is ISO 9001 and ISO 13485 certified. Visit the website at www.potomac-laser.com