Over the next few months, we are going to profile different materials that are optimized for micro manufacturing. This includes both rapid prototyping and full scale production. Now that Potomac is part of the Goodfellow family, we are in the enviable position of having access to the widest selection of materials in the world, available in various sizes, thicknesses, and form factors.

This month, we are kicking things off with a material that stands out in nearly every way. DuPont™ Kapton®, a polyimide film, has earned its reputation as one of the most versatile and reliable materials on the market.

Why Kapton?

Kapton is a high performance polymer film known for its exceptional thermal stability, chemical resistance, and mechanical strength. All of this is packed into a flexible, lightweight material. It performs reliably in extreme environments, withstanding temperatures ranging from -269°C to +400°C. That means it works just as well in outer space as it does in cutting edge medical or electronic applications.

You will find Kapton in everything from NASA spacecraft and Mars rovers, where it insulates electronics exposed to extreme temperature swings, to medical wearables and flexible sensors that require high durability and biocompatibility. It is also a critical material in foldable displays, printed circuit boards, lithium-ion battery insulation, and RFID antenna substrates.

Simply put, if your project demands a material that will not quit under pressure, Kapton is one you want to have in your toolkit.

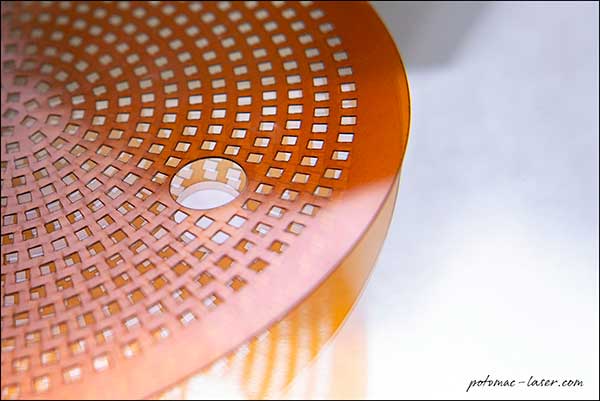

Micro Manufacturing at Its Finest

From a micro manufacturing standpoint, Kapton is in a league of its own. Our team at Potomac has been working with this material for years, and we continue to be impressed by how well it machines.

Using our UV laser systems, we can create features as small as 1 micron, holding submicron tolerances. This is a level of precision that very few can achieve. The result is extremely clean edges with no heat affected zone, preserving the material’s integrity even at the tiniest scales.

Whether you are prototyping a new design or ramping up to production volumes, Kapton is a material we know inside and out. We are ready to help you take advantage of its full potential.

Have a project in mind? Contact us today and send over your drawing. In most cases, we can turn around parts in a week or less.