Potomac’s Rapid Prototyping of Custom Microfluidic Devices Featured in Commercial Micro Manufacturing Magazine

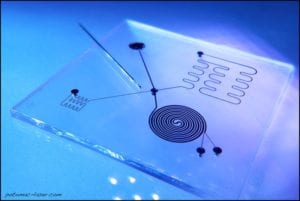

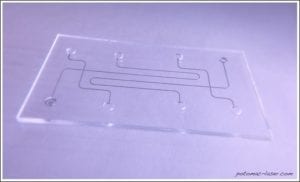

May 27th, 2015; Baltimore, MD: Potomac Photonics’ new program for rapid prototyping custom microfluidics devices was recently featured in Commercial Micro Manufacturing, a UK-based magazine for micro, high-precision and MEMS manufacturers. The feature article explains how Potomac uses digital fabrication technologies such as micromilling, laser micromachining, and hot embossing replication for a new type of virtual “vending machine” that manufactures custom microfluidic devices for the biotech and medical device industries.

Potomac’s Fast Track program uses an iterative CAD-based process to turn custom designs into fully functioning devices, reducing the time and expense of traditional fabrication processes. Digital fabrication also creates the affordable opportunity to optimize designs through testing and measurement of multiple alternatives. The innovative program saves time to market and ensures that new microfluidic devices have a greater chance of success in the field.

Working within specific manufacturing parameters, designers can get a minimum of 10 custom parts for just $90 per part. Of course, as volumes increase unit price is substantially reduced and can reach as little as $15 per part. Potomac can also go beyond the Fast Track program’s design constraints and create biotech devices with expanded features in additional materials. Cost would increase commensurately, but again the use of digital fabrication CAD processes would still offer quick turnaround.

To read the complete article entitled, Microfluidic Prototypes: a Virtual Vending Machine, please go to: https://www.potomac-laser.com/wp-content/uploads/2015/05/microfluidic-prototypes.pdf