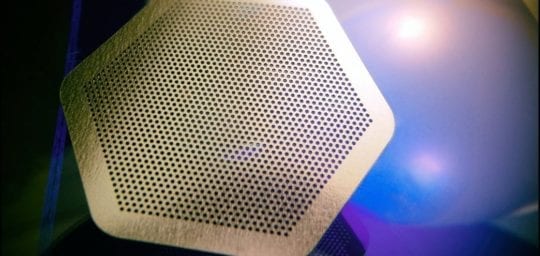

Precision Laser Micromachining to Help Launch a Polytechnique Montréal CubeSat into Space

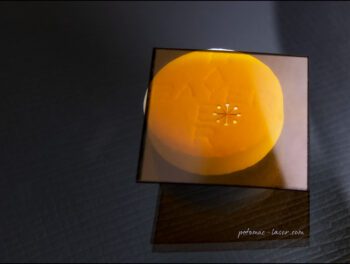

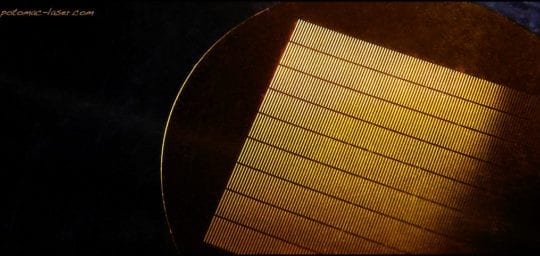

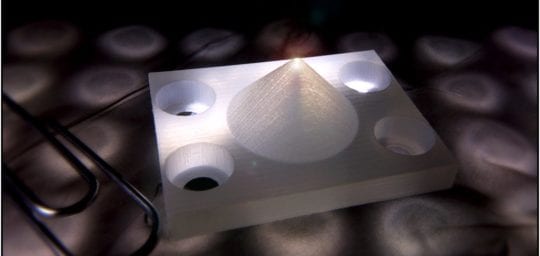

At Potomac we’re used to seeing some of the most interesting – and challenging – miniaturization projects on the planet. Recently we helped a Canadian university group miniaturizing for a space application. Polytechnique Montréal is competing in the Canadian Satellite Design Challenge (CSDC) and we were able to help laser micromachine micro holes for their…