Problem

At the time, our customer was using mask technology to generate their prototypes, which resulted in long lead times (6+weeks) because new masks had to be fabricated each time the design was modified.

Challenge

Provide a way to cost-effectively produce prototypes within 24-72 hours.

Solution

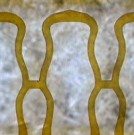

Utilizing software controlled, direct-write technology, Potomac was able to fabricate prototype parts directly from the customer’s CAD file. Potomac assembled a dedicated laser system that was readily available to manufacture parts the moment that new designs arrived via e-mail. In some cases, new drawings that were received in the morning were converted to finished parts by lunch and shipped from Maryland to California via courier for same day turnaround!

Conclusion

Potomac allowed the client to very quickly cycle through numerous design iterations, which allowed them to meet or beat investor milestones, begin clinical trials ahead of schedule, and get their product to market far more quickly than had been anticipated. Potomac values its partnerships and will always work hard with its customers to find complete solutions for all of their fabrication needs.