Phase I – Project Requirements

Potomac worked closely with client to understand all of the project requirements including technical specifications, materials timing, and cost targets. A Design for Manufacturing plan was completed with milestones and go/no-go criteria.

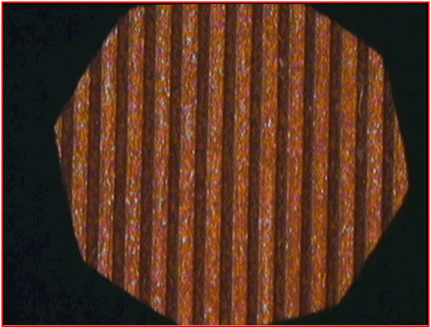

Phase II – Prototyping

Potomac developed manufacturing process and fabricated prototypes for customer testing and qualification. This phase required several iterations as customer worked to find an optimal design for their process.

Once the design was qualified and approved the project was ready to transition to production.

Challenge: Reduce prototype run rate of 5-hours/part to 4 minutes/part for high volume production (greater than 300,000 parts/year).

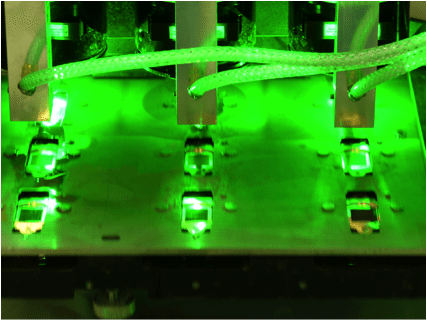

Phase III – Production:

Potomac designed and built a high power laser system with multiple beams capable of achieving the same specifications as the prototyping process with a overall run-rate of 3 minutes and 17 seconds / part. Within 3 months, 5 production systems were in service at Potomac running 24/7. Quality Assurance for the project met both ISO9001:2008 and PPAP requirements.