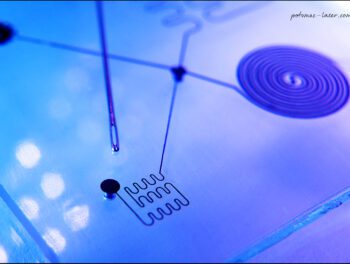

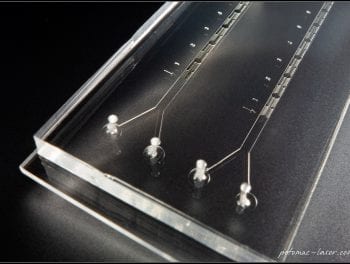

New NIST Heart on a Chip Microfluidic Platform Speeds Drug Discovery & Commercialization

Animal testing has long been an established protocol in drug discovery programs. But there are systemic issues with the far from reliable methodology. In fact, only 10% of the drugs that move from animal testing to human clinical trials succeeds. Such low yields increase the time and expense required to get pharmaceuticals to market, fueling…